Which Fabrication Method Leads To Pourous Metals Ceramics And Polymers

Journal of photopolymer science and technology 2020 33 5 573 582.

Which fabrication method leads to pourous metals ceramics and polymers. Products using ceramics metals and polymers 5. Hyperbranched polymers can be prepared by means of single monomer methodology smm and double monomer methodology dmm. While noted improvements have taken place in the area of ceramics and metals it is the field of polymers that has experienced an explosion in. Polymers are of great interest due to unique properties such as light weight corrosion resistance lower frictional properties less wear in.

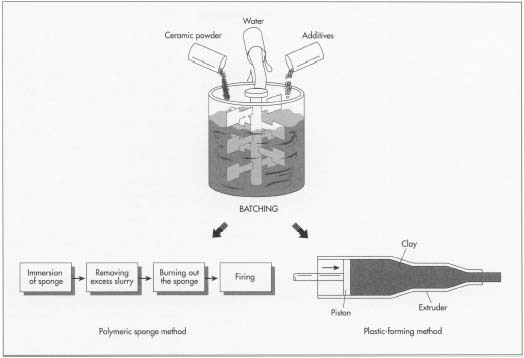

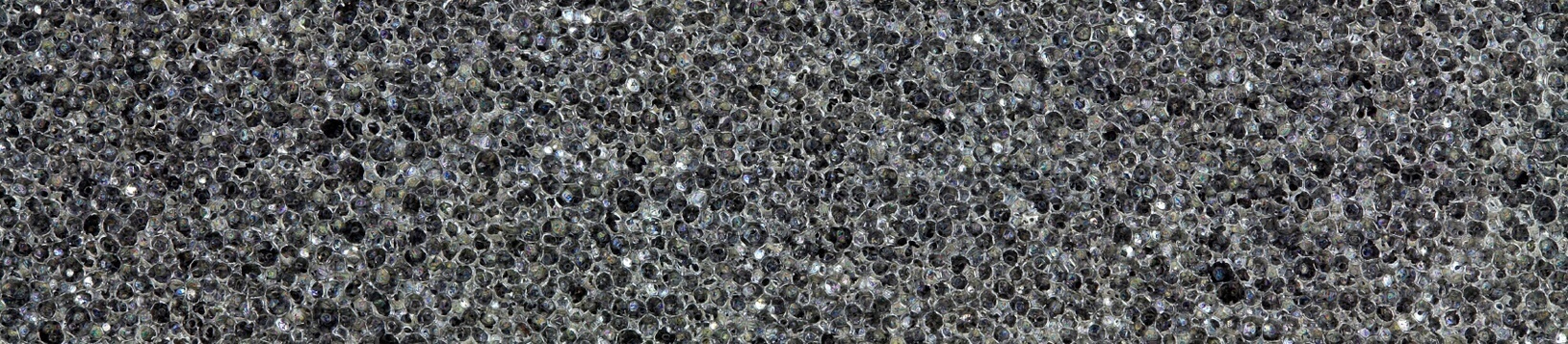

Laser ablation la which employs a pulsed laser to remove materials from a substrate for generating micro nanostructures has tremendous applications in the fabrication of metals ceramics glasses and polymers. Materials as a field is most commonly represented by ceramics metals and polymers. Best in tissue engineering using ceramics and polymers second edition 2014 1 5 2 porous ceramics porous ceramics have attracted great interest as scaffolds for tissue engineering particularly bioactive ceramics and glasses as they are able to bond to the host tissues. 5 lightweight protective materials.

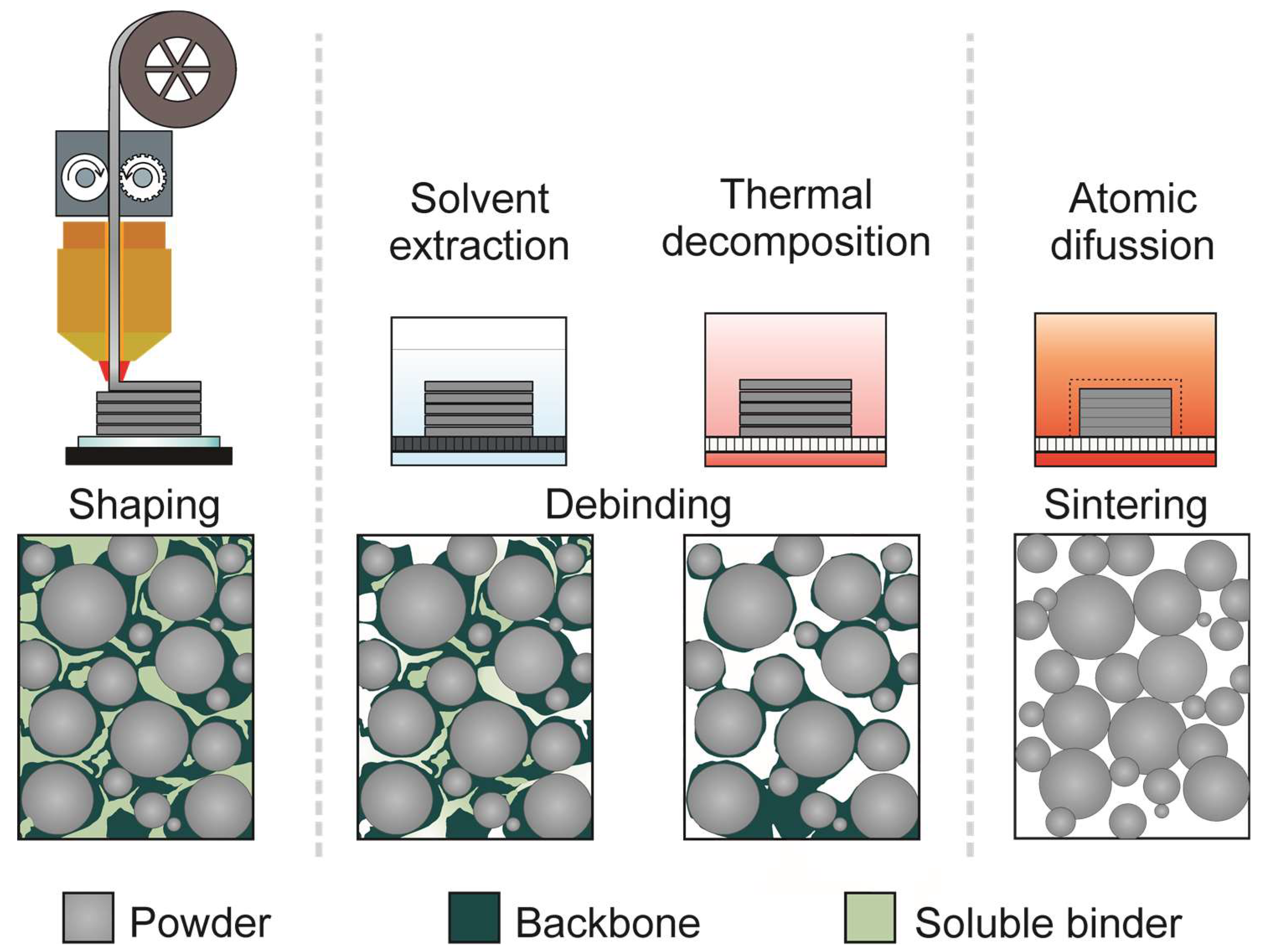

While several variations exist. Another recent processing method successfully employed in the medical electronics and armaments manufacturing sectors is particulate injection moulding pim 6 8. Laser ablation is widely used in the fabrication of metals ceramics glasses and polymers. Micro machining of metals ceramics and polymers using nanosecond lasers m r h knowles g.

Rapid prototyping techniques are fast evolving and gaining attention as they are being utilized for the fabrication of intricate structures of a variety of materials including polymers metals and ceramics. Ceramics polymers and metals overview and introduction the history of improving protection while reducing the weight of armor has been a remarkable materials success story.