Which Thermal Conditioning Process Is Used For Ceramic Products

A process that passes a product under a flowing stream of finishing material.

Which thermal conditioning process is used for ceramic products. But the process is different. Equipment used for injection molding is similar to that of extrusion. Ceramic materials can be identified by their general properties like high hardness brittleness chemical stability and low thermal conductivity. The feed material used for injection molding contains a mixture of ceramic powder with thermoplastic polymer plasticizer wetting agent antifoaming agent.

A thermistor is a type of resistor whose resistance is dependent on temperature more so than in standard resistors the word is a combination of thermal and resistor thermistors are widely used as inrush current limiters temperature sensors negative temperature coefficient or ntc type typically self resetting overcurrent protectors and self regulating heating elements positive. 11 7 2 process description1 3 5 figure 11 7 1 presents a general process flow diagram for ceramic products. Cutting material to shape using burning gasses. The types of commercial clays used for ceramics are primarily kaolin and ball clay.

These material properties are utilized to produce number of commercial and domestic products such as pottery bricks advanced functional items etc. Advanced ceramics and traditional ceramics are the main categories of ceramic materials. A thermal conditioning process used for ceramic products. Most ceramic products are clay based and are made from a single clay or one or more clays mixed with mineral modifiers such as quartz and feldspar.

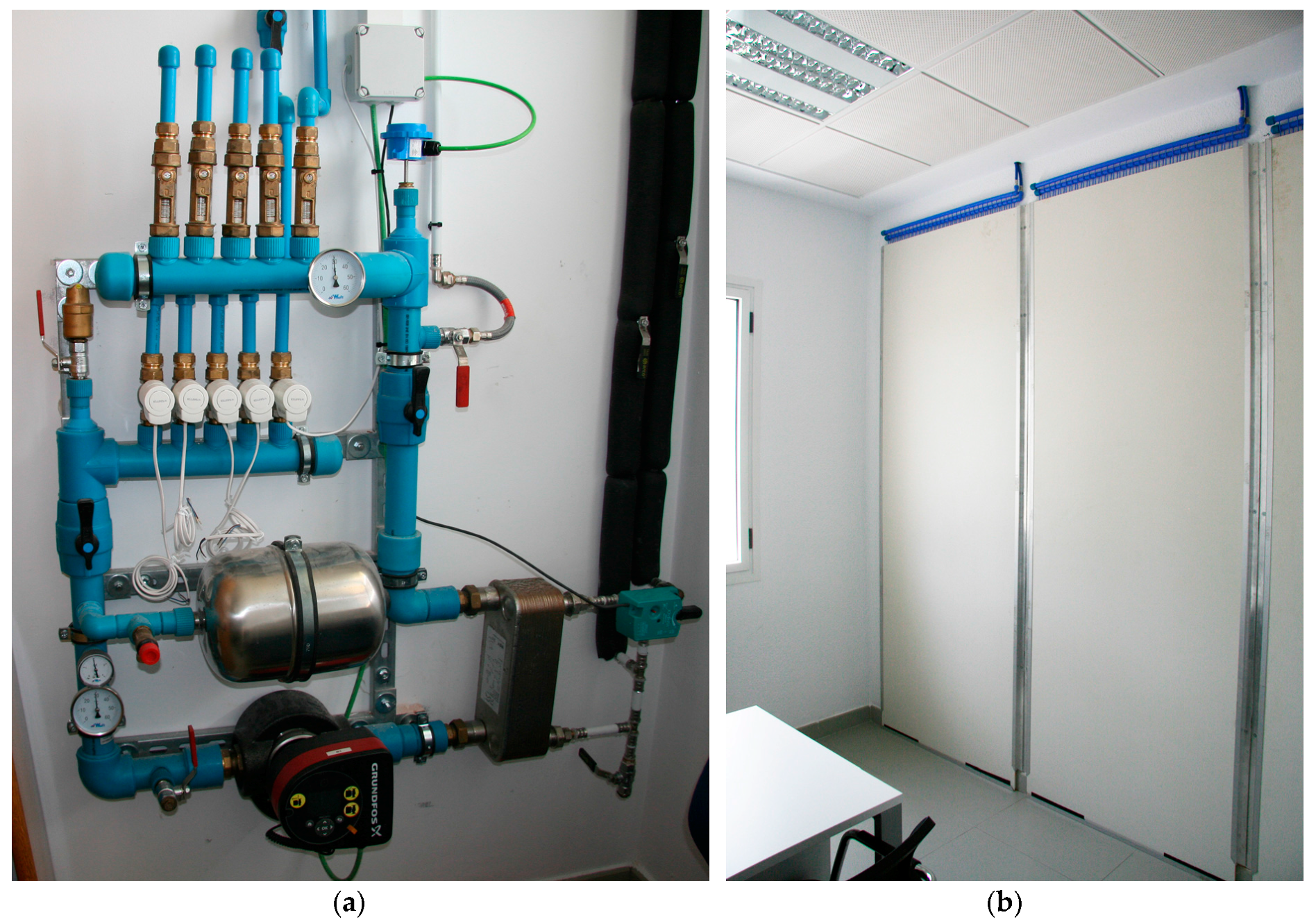

A method of joining materials using a metal alloy as bonding agent. Innovative thermal conditioning panel in ceramic material able to cool or heat any environment in a simple sustainable and energy efficient way the main advantages of this technology are.

.jpg)